Engineering Applications of Gas Spring Support Systems

1. Introduction

Gas spring support, sometimes called gas struts or gas lift supports, are mechanical devices that use compressed gas to provide controlled force for lifting, lowering, and supporting objects. Unlike traditional mechanical springs, gas springs offer smooth, adjustable, and precise motion control, making them ideal for modern engineering applications.

2. How Gas Spring Supports Work

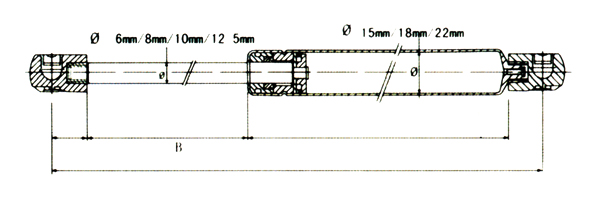

A typical gas spring consists of:

Cylinder: Contains pressurized gas (usually nitrogen).

Piston Rod: Moves in and out of the cylinder to create a force.

Seals and Dampers: Ensure smooth motion and prevent leaks.

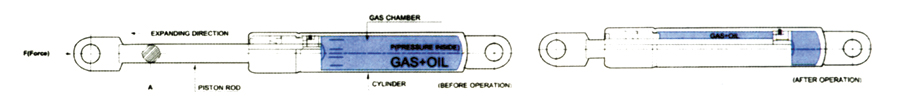

When the piston rod is pushed into the cylinder, the compressed gas resists motion, storing energy. When the rod extends, it releases energy to assist lifting or holding the load. Some gas springs include damping mechanisms for slow, controlled movement.

3. Types of Gas Spring Supports

Standard Gas Springs: Provide uniform force for lifting or counterbalancing weights.

Adjustable Gas Springs: Allow force adjustments for different loads.

Lockable Gas Springs: Can lock in position for stability.

Dampened Gas Springs: Control speed and prevent sudden movements, useful for safety-critical applications.

4. Key Engineering Applications

a) Automotive Industry

Hood and Trunk Supports: Gas spring lift support make opening and closing smooth, reducing strain on users.

Tailgate Lift Systems: Help lift heavy tailgates effortlessly.

Seat Adjustment Mechanisms: Enable smooth recline and height adjustments.

b) Aerospace and Transportation

Overhead Bins and Panels: Gas springs help secure and assist in opening/closing compartments.

Aircraft Seats and Cargo Systems: Offer precise motion control under variable loads.

c) Industrial Machinery

Machine Guards and Hatches: Gas springs allow easy access to machinery while ensuring safety.

Robotic Arms and Equipment Doors: Smooth motion reduces wear and improves operator safety.

d) Furniture and Consumer Products

Cabinets and Lift-Up Beds: Gas springs reduce effort and prevent accidental slamming.

Ergonomic Chairs: Gas spring lift mechanisms enable height adjustment with ease.

5. Advantages in Engineering Applications

Controlled Motion: Reduces sudden movements, preventing injury or damage.

Load Management: Counterbalances heavy weights, minimizing effort.

Compact Design: Saves space compared to mechanical alternatives.

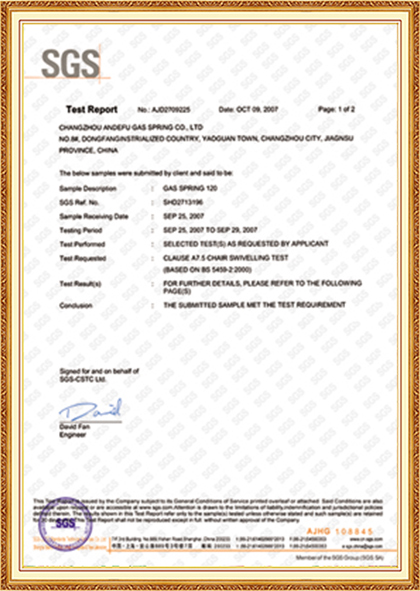

Longevity: High-quality gas strut lift support can last thousands of cycles.

Customizability: Adjustable force and damping cater to specific engineering needs.

6. Design Considerations

When integrating gas spring support systems, engineers must consider:

Load Weight and Center of Gravity: Determines the required spring force.

Stroke Length: How far the spring must extend or compress.

Mounting Orientation: Vertical vs. horizontal mounting affects performance.

Environmental Conditions: Temperature and exposure to moisture or chemicals can impact longevity.

Safety Requirements: Damping or locking features may be necessary to prevent accidental motion.

7. Emerging Trends

Smart Gas Springs: Equipped with sensors for position feedback.

Lightweight Materials: Aluminum and composites reduce weight for aerospace and automotive use.

Hybrid Systems: Combining gas springs with electric actuators for precision motion control.