Lockable vs Standard Gas Springs: Key Differences You Need to Know

Gas springs are widely used in applications ranging from office chairs and automotive hoods to industrial machinery. They provide controlled lifting, lowering, and positioning of heavy objects, making tasks easier and safer. However, not all gas springs are created equal. Two common types you’ll encounter are standard gas springs and lockable gas springs, each designed for specific applications. Understanding their differences is crucial to selecting the right one for your needs.

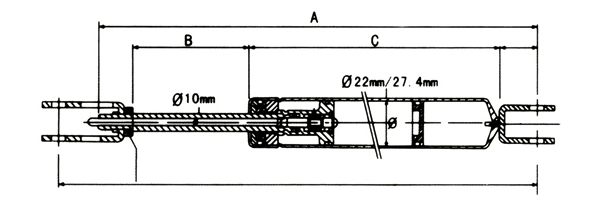

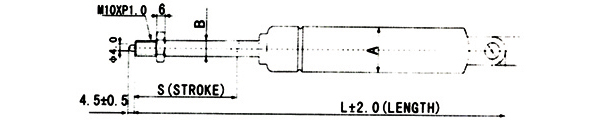

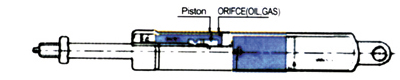

A standard gas spring operates using pressurized gas contained within a cylinder and a piston rod. When force is applied, the gas compresses or expands, creating a controlled motion. These gas springs provide smooth, predictable movement but do not lock in a particular position. Once external force is removed, they naturally return to their default position, which can limit their use in applications where stationary positioning is required.

Lockable gas springs, on the other hand, include an additional mechanism that allows the piston rod to be locked at any desired position. This locking feature gives users precise control over movement and ensures that the gas spring remains stable, even when external forces are removed. This makes lockable gas spring ideal for applications where objects must remain fixed in place temporarily, such as medical equipment, adjustable desks, or automotive hoods.

One of the most obvious differences between the two types is functionality. While standard gas springs excel at assisting movement and providing cushioning, they are not suitable for holding a load in place without continuous support. Lockable gas struts combine this motion support with the ability to securely hold objects in position, providing a dual function that standard gas springs cannot achieve.

Safety is another important distinction. Standard gas springs rely solely on the gas pressure to maintain force. If the spring fails, objects may move unexpectedly, creating potential hazards. Lockable gas springs enhance safety by allowing the user to lock the spring in place, reducing the risk of sudden drops or uncontrolled movement. This feature is especially valuable in industrial and medical environments where precision and safety are paramount.

Adjustability is also a key differentiator. Standard gas springs have a fixed force rating and limited adjustability once installed. In contrast, lockable gas springs allow users to lock and unlock the spring at various positions, offering a higher level of versatility. This makes them suitable for dynamic applications where the height or angle needs frequent adjustments without compromising stability.

Another difference lies in cost and complexity. Standard gas springs are typically simpler and more affordable due to their straightforward design. Lockable gas springs are mechanically more complex, often incorporating internal locking mechanisms or external controls. While they may have a higher upfront cost, the added functionality and safety features often justify the investment in professional or heavy-duty applications.

Maintenance and lifespan considerations also differ. Standard gas springs are generally low-maintenance but may wear out faster if used to hold heavy loads for extended periods. Adjustable locking gas springs, because of their locking mechanism, may require occasional inspection or lubrication to ensure the lock continues to operate smoothly. However, their ability to lock positions can also reduce wear by minimizing continuous movement under load.